The control layer.

From bench, to crane, to cash.

Use one tool to secure daily output, cut rework at source and prevent last minute surprises across manufacturing & delivery.

CONSTRUCTION ASSEMBLY SOFTWAREIt’s a tough market out there.Why are leaders deploying Artic?

“Prevent last minute surprises”

“Track & prevent rework”

“Secure daily production output”

“Level production loads”

“Control drawings”

“Correct performance loss”

“Align design → production → install”

“Track labour efficiency”

“Prevent last minute surprises” “Track & prevent rework” “Secure daily production output” “Level production loads” “Control drawings” “Correct performance loss” “Align design → production → install” “Track labour efficiency”

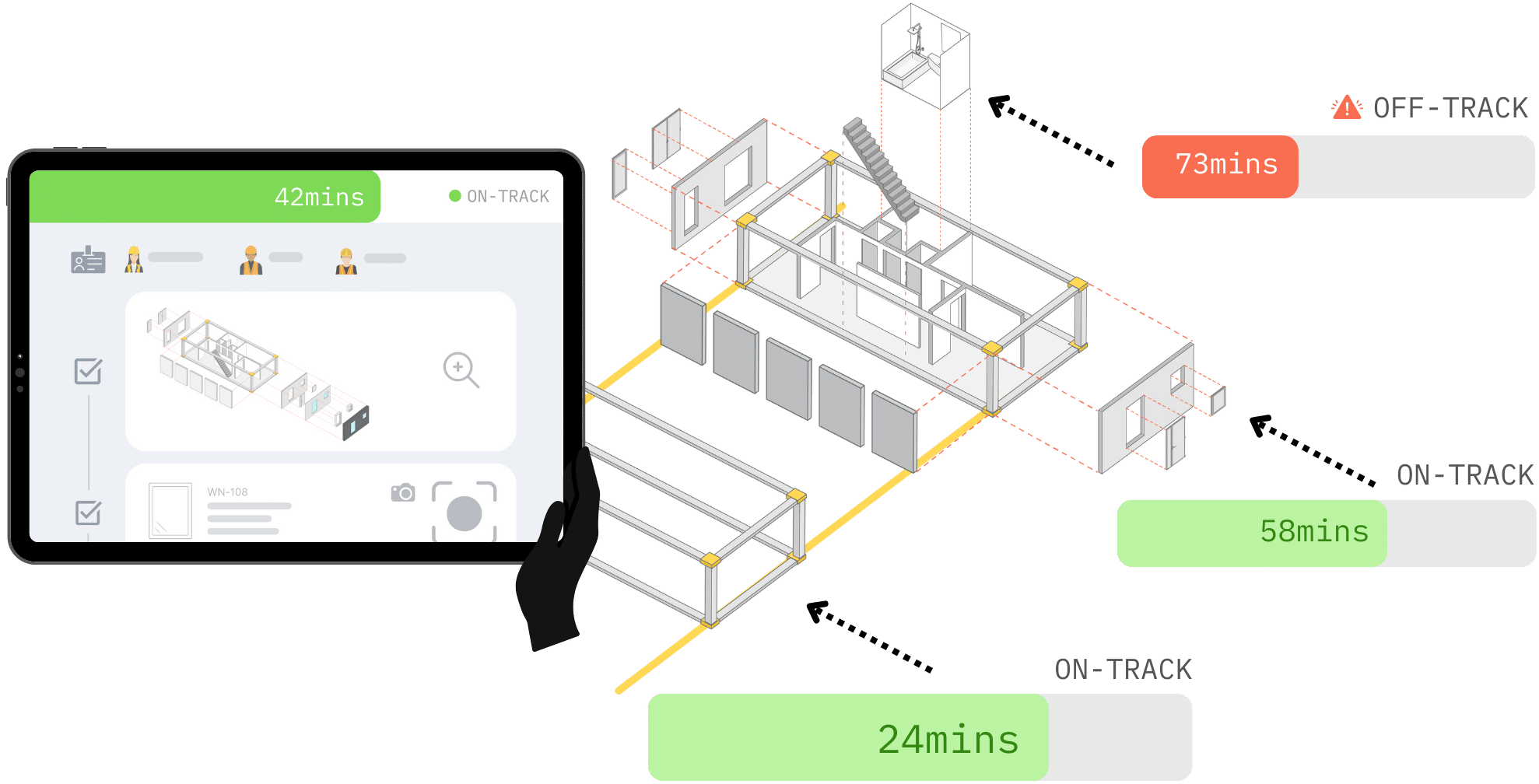

Secure daily output

Correct performance loss. Fast.

Leaders struggle to drive discipline without live control. Artic fixes that.

Lift floor performance with live pacemakers, downtime monitors and process control. Surface issues and fix them fast.

Use Artic to generate line-balanced production plans, reducing bottlenecks, increasing flow.

18%+

THROUGHPUTOffsite manufacturers like you are deploying Artic. Here’s why.

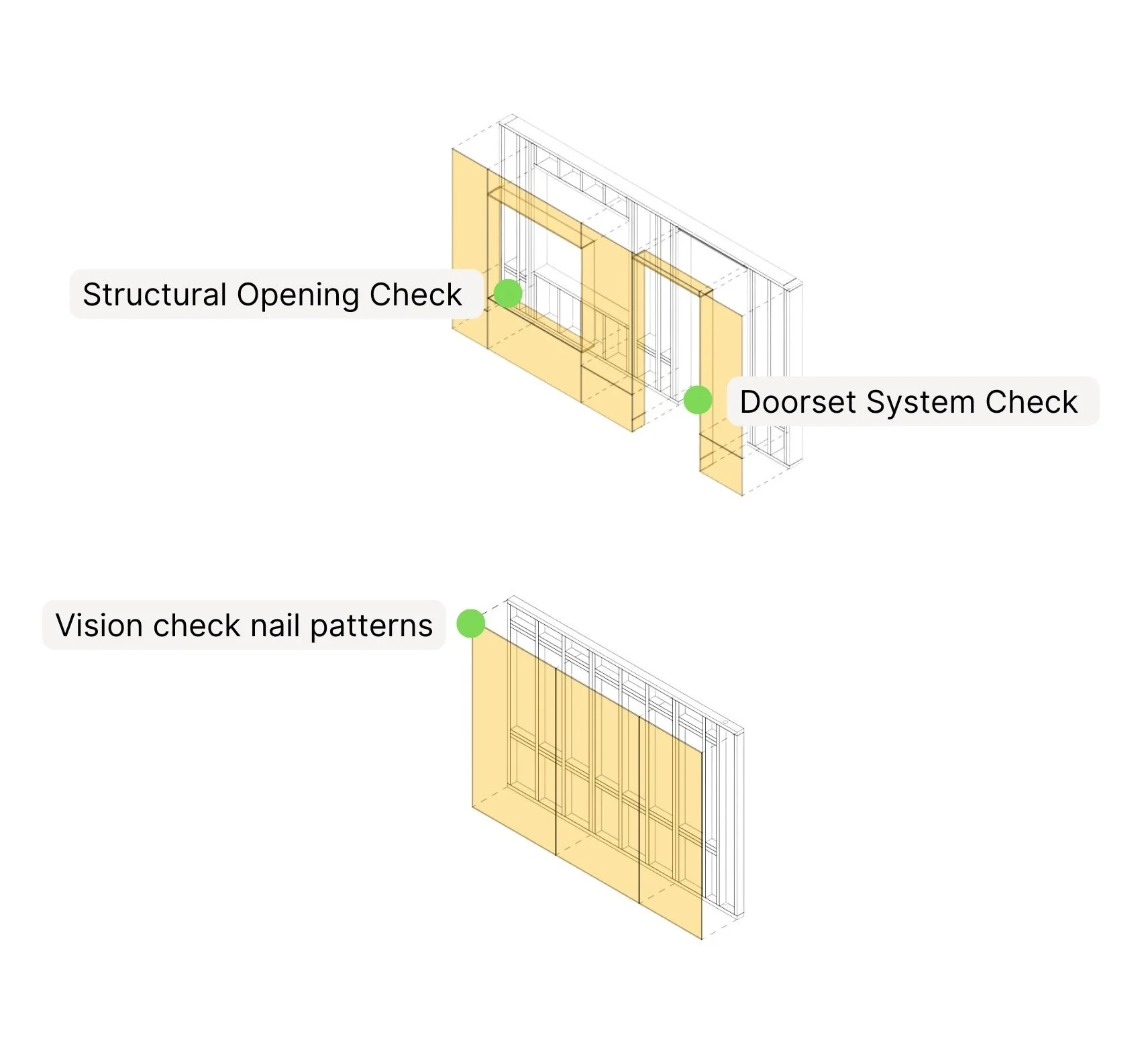

Control quality against the actual assembly design.

Not generic checklists that leak rework.

Hold the line across manufacturing + installation stages. Properly.

Stop relying on generic lists.

Artic scans your drawings to set a robust quality inspection plan for each of your assembly’s architectural details.

Ensure build-in quality at each step with in-process photo checks 📸

Prevent the risk of margin leaking site rework with Dispatch Checks.

57%

Cut in ReworkNo more last-minute shocks.

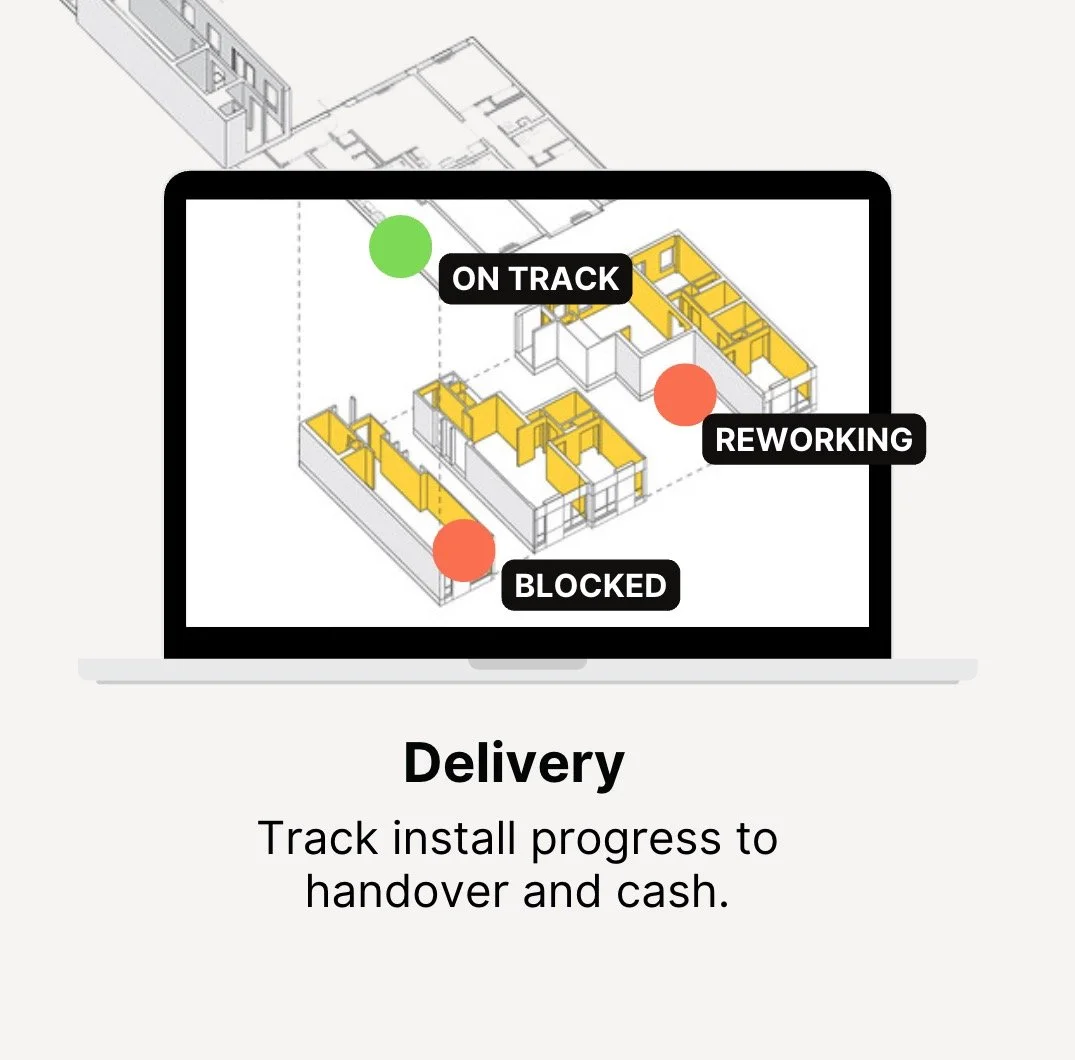

Take the stress out of delivery.

Take the spiralling costs out of production.

Use one tool to verify progress, tracking performance against plan across your manufacturing and install stages.

Introduce a quality of life improvement for your team that drives a P&L improvement for the board pack.

For People Like You.

-

Give teams what they need to coordinate their effort and get projects to practical completion on time. Put a system in place that generates a 4x return on your investment.

-

Stay focused on value-add work—Artic automates reporting, schedules, drawing allocation and quality documentation.

-

See around the corner. Submit your required delivery dates and get a live view of when your building systems will land on site, complete with drawings, quality and installation sequencing.

-

Move accountability for Quality to where the work is actually done. Spend less time documenting issues with a control system that sets standards and prevents issues altogether.

-

Spend less time responding to RFI’s, less time with Operators standing at the end of your desk and more time modelling.

DESIGN PARTNER

Artic is developed with input from Sekisui House—the world’s largest prefabrication manufacturer—so you can implement best-in-class software for your business.

“Artic’s technology automatically identifies prefab systems meaning the time to deploy is quick and we were able to hit production rate improvements in 6 months instead of 18 months.

Yoshi Ishimoto - Production Headquarters

Sekisui House, Japan

Pilot Availability

✔✔✔✔✔✔☉☉☉☉

4 slots remaining for 2025.

Built by former architects, design engineers & offsite manufacturing pros.

We’ve worked the job and we’ve felt the struggles of the day first-hand. We’ve poured that knowledge into Artic to develop a system that unlocks real savings for your business.

Fully integrates with the tools you use

“Offsite Manufacturing & Assembly Software”

“Artic dispatches takt times, creates schedules and controls build quality from the production lines right the way through to ‘move-in-time’. This gives real time visibility of programmes for manufacturers, clients and project stakeholders.”

🇺🇸

Greystar - Modern Living Solutions uses Artic to accelerate the delivery of their breakthrough modular, build-to-rent offering.

🇮🇪

Vision Built are using Artic to manufacture market-leading portable schools and hospitals across UK & Ireland.

🇬🇧

Ibstock are using Artic to manufacture, deliver & track their precast facade systems to sites.

🇬🇧

With over 25 years of experience, Lowfield use Artic to deliver their structural timber systems for the new homes we all need.

🇬🇧

Innovaré Offsite use Artic to manage production, delivery scheduling & quality for their net-zero schools and more.

🇬🇧

ESS Modular deploy Artic in multiple factories to deliver some of the biggest offsite construction programmes in the world.

🇫🇷

Ademeure are piloting Artic to setup and scale their offsite manufactured homes across France & beyond.

🇬🇧 + 🇯🇵

Urban Splash + Sekisui House, use Artic to deliver their award-winning Town House.

Dr. Raymond Levitt

Founder, Stanford—Advanced Project Management. Blackhorn Ventures, Operating Partner.

“We’ve seen multiple attempts to manage construction prefabrication operations with Manufacturing Management Systems (MMSs).

Unlike previous MMSs we have seen, Artic is built on a lean management foundation and supports manufacturers with ever-changing onsite project schedules.

Artic’s breakthrough then, is enabling construction prefab manufacturers to be flexible, efficient and high output— coordinating all the workstreams for faster, more profitable offsite delivery.”